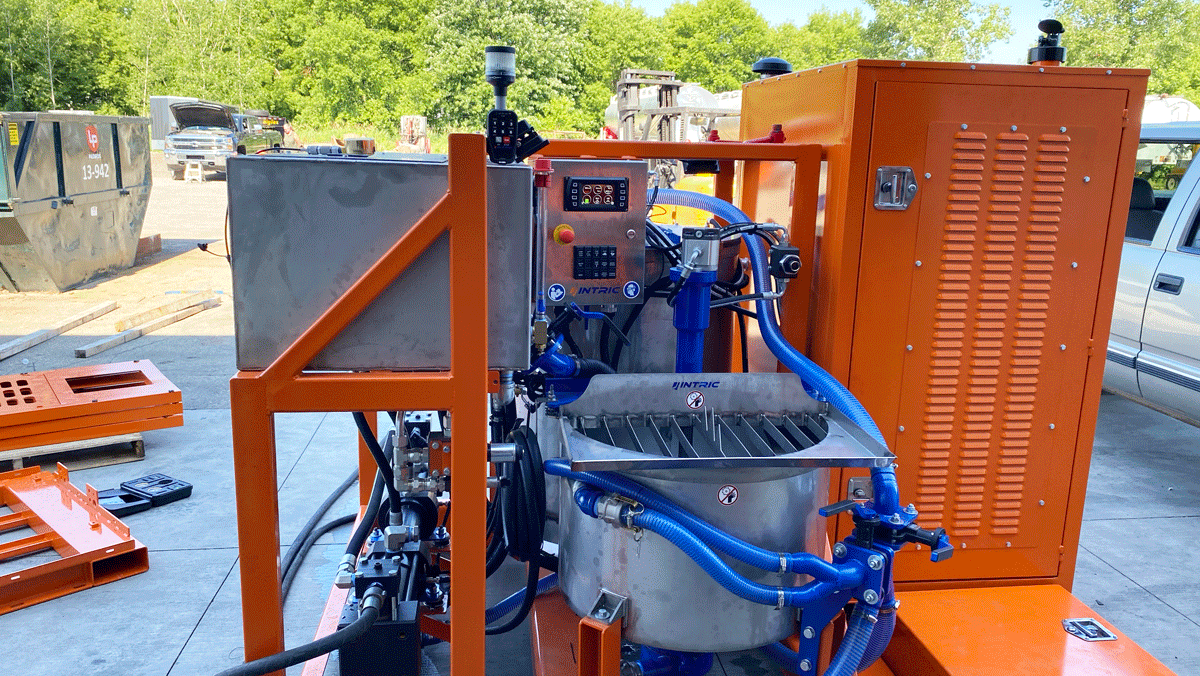

Intric D12 American‑Made High Shear Colloidal Grout Plant for Rent or Sale – Skid‑Mounted Diesel‑Powered Mixer and Pump for Micropile, Anchor, Soil Nail, and Ground Improvement Grouting Applications, Delivering High‑Pressure, High‑Volume Colloidal Mixing Performance for Demanding Foundation and Infrastructure Projects

Intric D12 Grout Plant Specs & Typical Jobs

Intric D12 Grout Plant – Key Specs

- Proudly made in the USA

-

High-shear colloidal mixer and grout pump for cementitious grouts on a compact skid-mounted frame.

-

60 gal stainless steel mixing tank with bag-ripper hopper and approximately 150–170 gal holding tank.

-

Delivers around 60 GPM grout flow and up to about 1800 PSI pressure (not simultaneously).

-

Variable-speed hydraulic mixer and double-acting piston pump with check valves for consistent, high-energy mixing.

-

Detachable Kubota diesel power pack with integrated hydraulic and fuel tanks plus cooling system.

-

Digital control panel with readouts for pressure, flow, stroke count, and calculated volume, plus semi-automatic water dosing.

-

Integrated forklift pockets and lifting points for easy loading, unloading, and positioning on tight jobsites.

-

Abrasion-resistant grout lines and service-friendly layout to simplify cleaning, maintenance, and pump rebuilds.

Typical Intric D12 Job Applications

- Micropile foundations for new construction and structural retrofits in tight-access sites.

- Tieback and ground anchor grouting for retaining walls, shoring, and excavation support.

- Soil nail and general ground improvement grouting to stabilize slopes, embankments, and weak soils.

- Underpinning and rehabilitation beneath existing buildings, bridges, and industrial facilities.

- Rock, curtain, and permeation grouting where high-energy mixing and dependable suspension are critical.

The Intric D12 overview

Intric D12 is the second model in the INTRIC grout plant line, built on more than 15 years of deep foundation field experience to deliver higher output for serious production grouting. Delivering up to 60 GPM at pressures up to 1800 PSI, it provides the extra capacity contractors need for larger micropiles, anchors, soil nails, jet grouting, and other demanding grout applications. With a 60-gallon high‑shear colloidal mixing tank and a 170-gallon storage tank, the D12 is engineered to keep grout quality high while extending run time between batches so crews stay productive on tight, complex jobsites. INTRIC grout plants mix colloidally and with high shear, giving you fast cement dispersion and the ability to add materials like sand, silica, or lime without sacrificing suspension or pumpability, while integrated data capture lets operators record and log grout volumes by day or per pile for built‑in QA/QC and reporting. The D12 is available for rent or sale, sells and ships internationally, and is stocked by National Piling Products so it’s ready when and where you need it as part of a complete, field‑proven deep foundation package.

Why rent or buy the Intric D12 from NPP

National Piling Products is a deep foundation specialist serving the micropile, anchor, and soil nail market with rental equipment, Intric grout plants, materials, load testing, and field consulting. Because the D12 lives in the NPP rental fleet as well as the sales line, it shows up configured for real‑world, high‑production grouting, supported by a team that understands how to dial in flows, pressures, and mixes for challenging ground conditions. As a distributor for Intric Grouting Solutions, NPP carries D12 plants, pumps, and wear parts in stock, helping contractors boost production and uptime whether they choose a long‑term purchase or a short‑term rental.

Partner the D12 with the right drill

The Intric D12 really shines as part of a complete deep foundation package, paired with specialty limited‑access drill rigs for larger‑diameter or higher‑capacity micropile and anchor installations. National Piling Products is a leader in micropile drill rigs, excavator attachments, and heads, renting and selling TEI Rock Drills and Comacchio drill rigs that match seamlessly with Intric grout plants on confined, low‑headroom, and hard‑to‑reach sites. By partnering the D12 with TEI and Comacchio rigs from the NPP fleet, contractors get an integrated drilling and grouting solution where drill string sizes, grout volumes, and pressures are aligned to keep production on track from the first pile to the last.

Top‑notch mechanic shop and support

NPP’s operation is anchored by a mechanic group with years of specialty setup and repair experience on deep foundation equipment, including Intric grout plants, Comacchio rigs, TEI attachments, and other fleet machines. The shop maintains the rental fleet, services pumps and hydraulic systems, and supports your crews through startup, production, and demobilization so the D12 stays productive on demanding jobs instead of becoming a bottleneck. Whether you own or rent the D12, you get the same responsive support behind the iron.

Get in touch

Visit the National Piling Products YouTube channel for field support videos, Intric D12 walk‑throughs, and display overviews, and reach out with ideas for how‑to content tailored to your teams. For D12 rentals, sales, or application questions—or to discuss pairing the D12 with TEI or Comacchio drill rigs—call 1‑855‑801‑7453 to talk with the National Piling Products team.