Intric DT650 Key Specs and Job Types

DT650 Mixing Station – Key Specs

-

Made in the USA, high‑capacity grout and slurry mixing station for large projects.

-

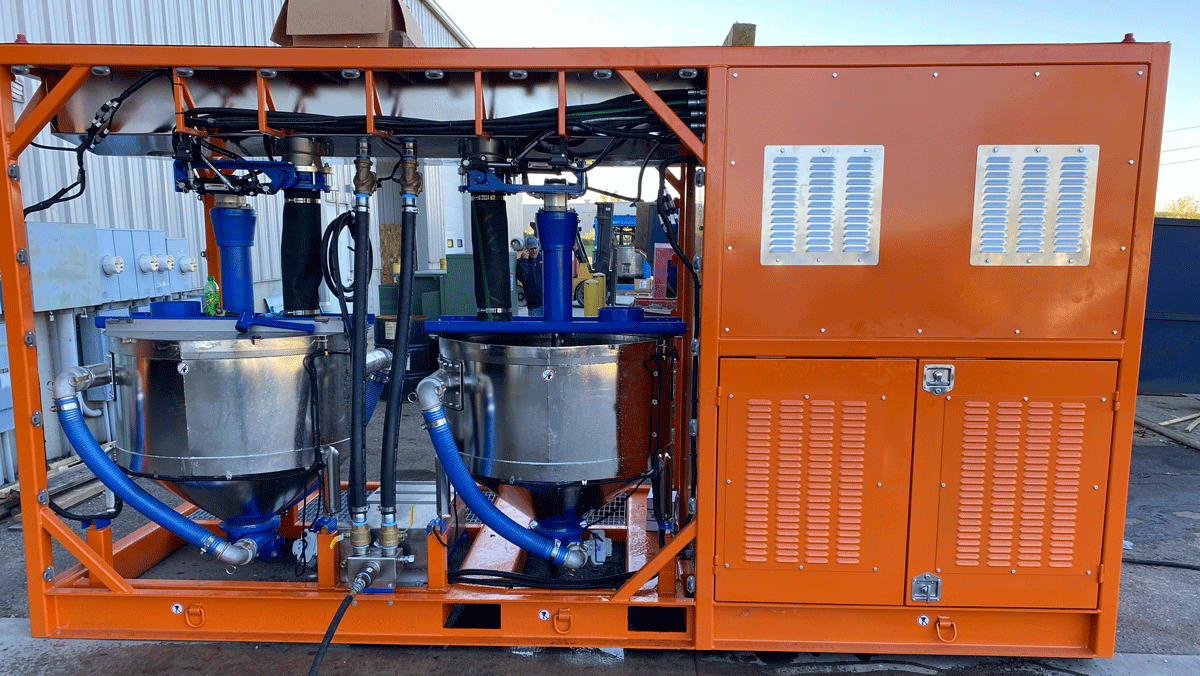

Dual stainless steel mixing tanks, each about 170 U.S. gal (650 l), for a total of 340 U.S. gal of mixed material on board.

-

High‑shear colloidal mixing tools with adjustable speed up to 1800 rpm for fast, uniform grout, even at low water‑cement ratios.

-

Fully automatic water dosing and preset mix recipes for repeatable batching with minimal operator input.

-

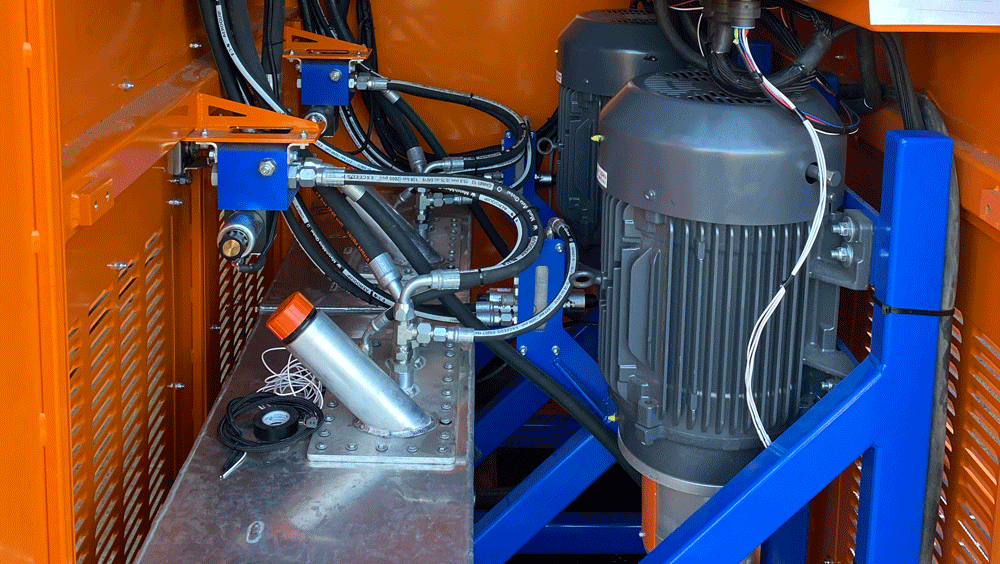

Integrated hydraulic system powering mixers and agitators for reliable continuous‑duty operation.

-

Skid‑mounted steel frame with forklift pockets for easy transport and setup on tight jobsites.

-

Approximate dimensions 75 in W x 180 in L x 96 in H, with operating weight around 8,200 lb for a stable working platform.

-

Onboard pressure washer and six work lights to keep the plant clean and productive in low‑light conditions.

Typical Intric DT650 Job Applications

-

High‑volume micropile and ground anchor projects that need continuous, high‑quality grout output.

-

Large soil nail and slope stabilization jobs where dual tanks maintain steady production and minimize downtime.

-

Infrastructure, tunneling, and industrial ground improvement work requiring reliable, automated grout mixing at scale.

Intric DT650 overview

The Intric DT650 is a Made in the USA, high‑capacity dual‑tank mixing station built to give contractors consistent, high‑quality grout and slurry production on large deep foundation and infrastructure projects. With two stainless steel high‑shear mixing tanks providing roughly 340 gallons of total mixed volume, it delivers repeatable batches with precise material and water control so crews can keep pumps fed and production moving on busy jobsites. Designed with automated controls, load‑cell feedback, and recipe‑based batching, the DT650 standardizes grout quality across shifts and multiple projects instead of relying on manual mixing and operator guesswork. Available for rent or sale through National Piling Products, the DT650 can be mobilized quickly as part of a complete, field‑proven grouting package tailored to demanding micropile, anchor, and soil nail work.

Why rent or buy the Intric DT650 from NPP

National Piling Products specializes in deep foundation and grouting solutions, supplying rental drill rigs, Intric grout plants and mixing stations, materials, load testing services, and field consulting dedicated to micropiles, anchors, and soil nails. Because the DT650 lives both in the NPP rental fleet and on the sales line, it arrives configured for real‑world production grouting—control settings, flows, and recipes tuned for neat and sanded mixes—rather than as a bare factory machine. As an authorized Intric distributor, NPP keeps DT650 units and critical wear components in stock, helping contractors increase production and uptime whether they choose a long‑term purchase or a project‑specific rental.

Pair the DT650 with the right pump and drill

The Intric DT650 really shines as part of a complete grouting system, paired with Intric pump stations and, on larger jobs, D‑series grout plants that can take advantage of its high output. National Piling Products can match the DT650 with high‑shear pump packages and limited‑access drill rigs so drilling, mixing, and pumping capacities stay aligned from submittals through production. By combining the DT650 with TEI and Comacchio rigs and additional Intric grout equipment from the NPP fleet, contractors get an integrated drilling and grouting solution where mix designs, volumes, and pressures are coordinated to keep piles, anchors, and nails advancing without starving the pumps.

Top‑notch mechanic shop and support

NPP’s operation is backed by a mechanic team with years of specialty setup and repair experience on deep foundation equipment, including Intric mixing stations and grout plants, Comacchio rigs, and TEI attachments. This shop maintains the rental fleet, supports custom DT650 configurations, and assists your crews through commissioning, production, and demobilization so the mixing station remains an asset instead of a jobsite bottleneck. Whether you own or rent the DT650, you get the same responsive technical and mechanical support standing behind the equipment.

Get in touch

Visit National Piling Products’ YouTube channel for equipment walk‑throughs, mixing tutorials, and field tips focused on micropile and anchor grouting. For DT650 rentals, sales, or application questions—or to discuss pairing the DT650 with Intric pumps and TEI or Comacchio drill rigs—call 1‑855‑801‑7453 to speak with the National Piling Products team.