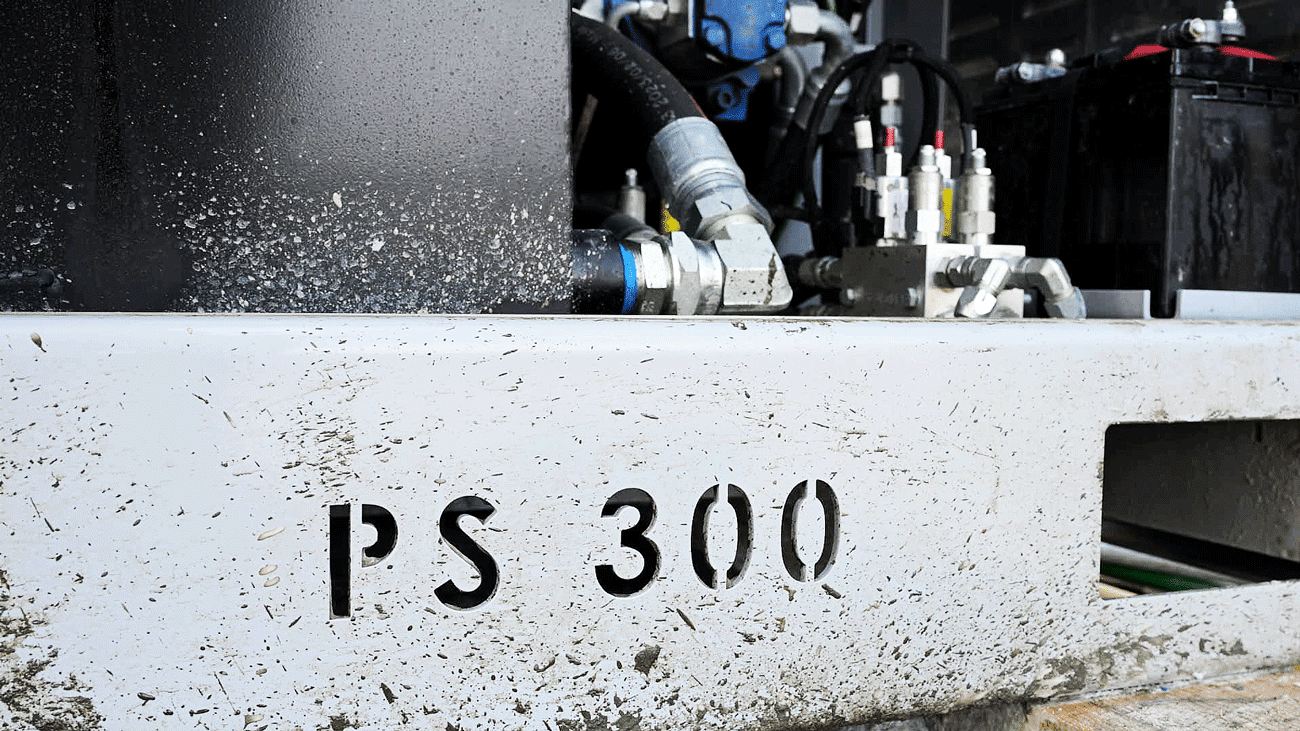

Intric PS-300 Pump Station Specs & Job Types

Top 8 specs – Intric PS‑300 Pump Station

-

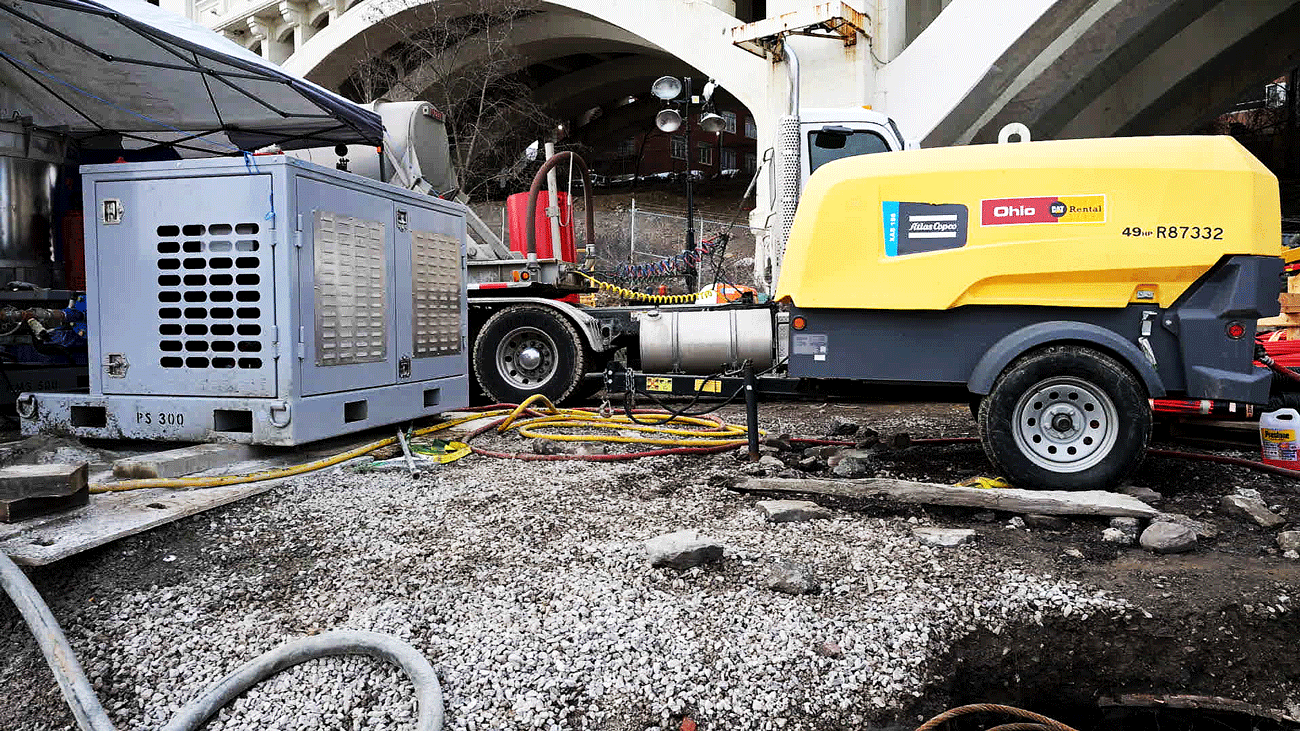

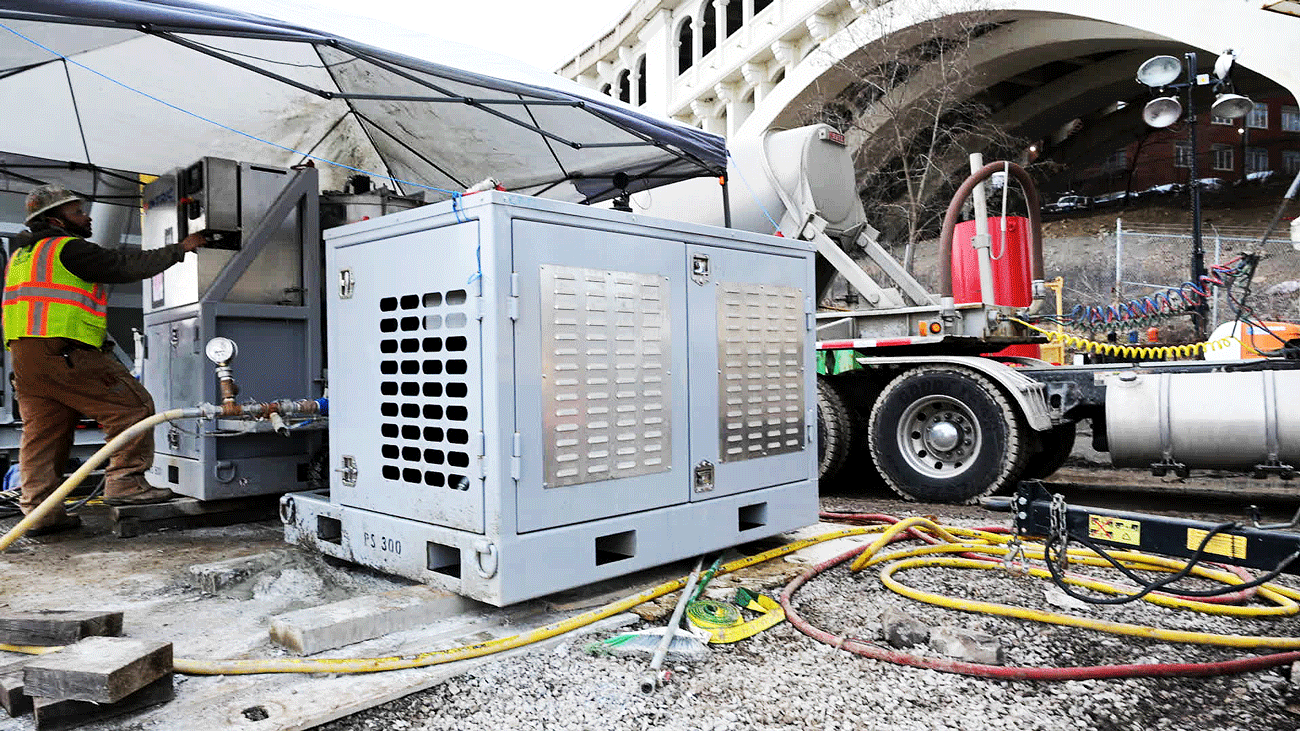

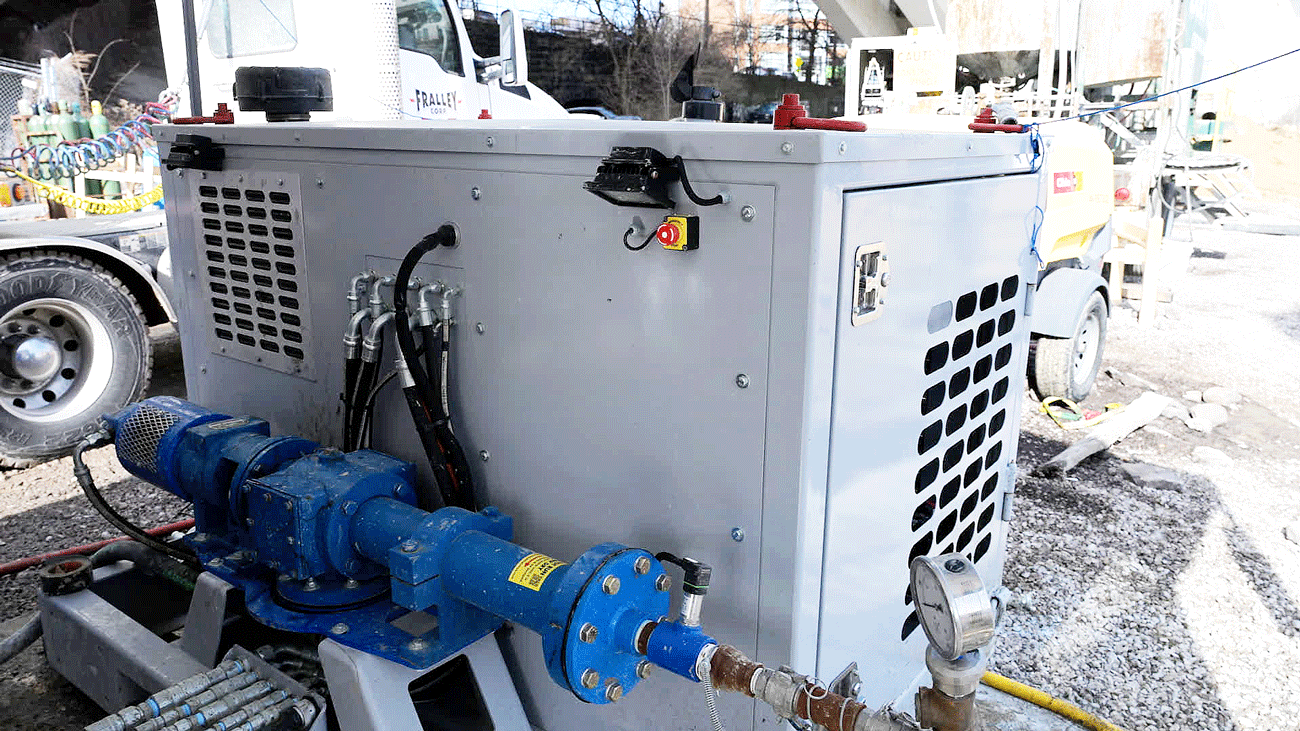

Modular grout pump station on a heavy‑duty skid with forklift pockets for easy loading and positioning.

-

65 HP Kubota Tier 4 Final diesel engine with liquid cooling for reliable, fuel‑efficient power.

-

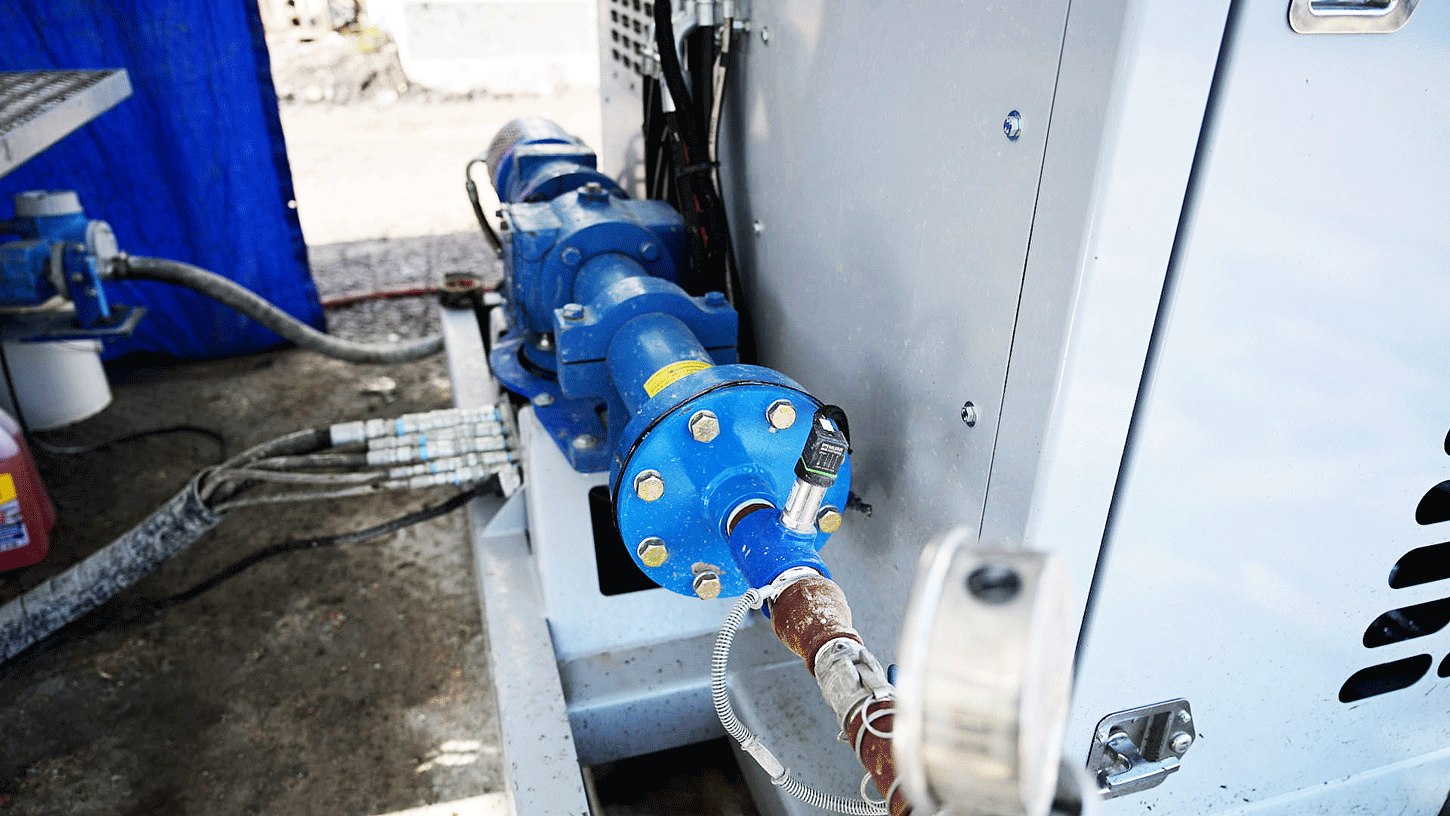

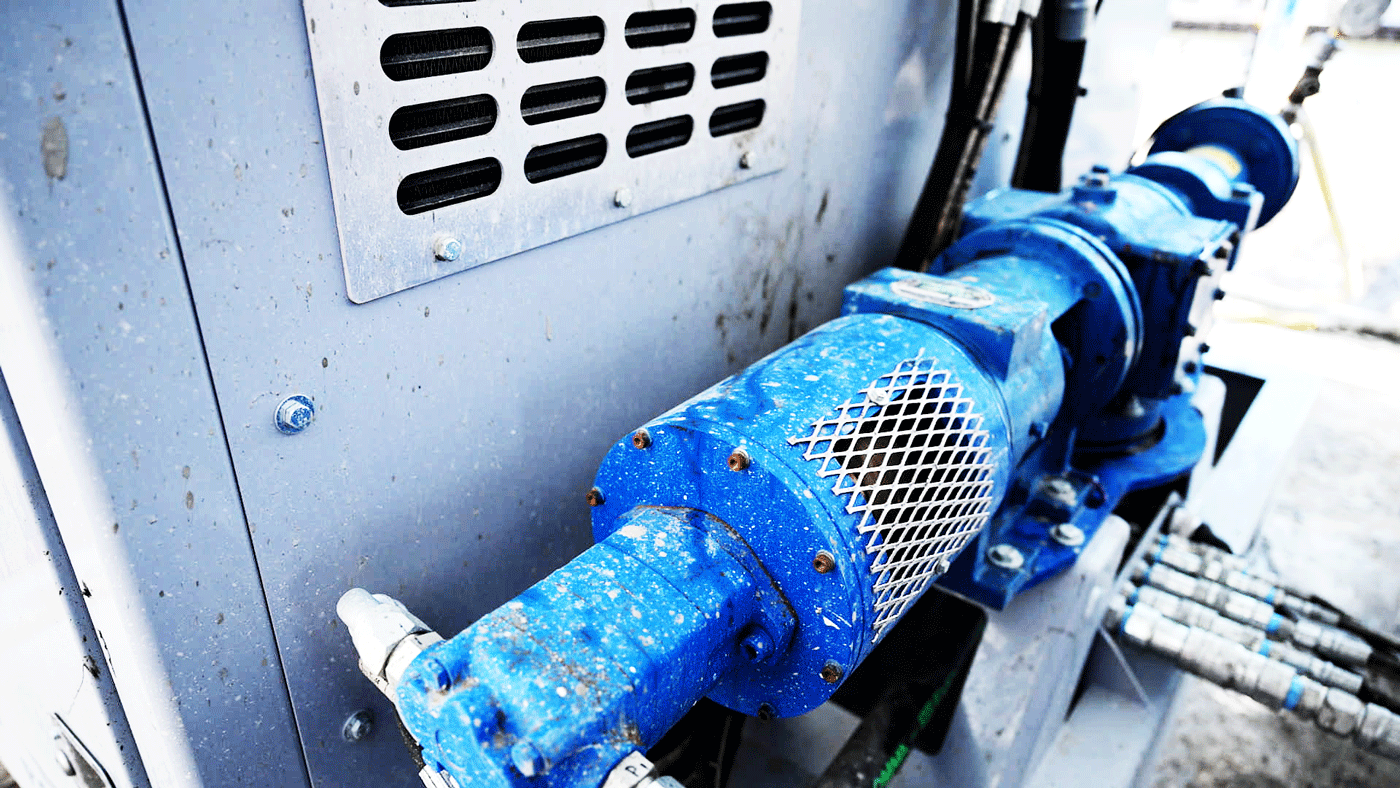

Hydraulic system with 50‑gallon oil tank, cooling fan, and high‑pressure filtration to protect components.

-

Single hydraulic‑driven, double‑acting piston grout pump in horizontal configuration for smooth output.

-

Maximum grout flow up to 80 gallons per minute for high‑volume grouting tasks.

-

Maximum pressure up to 1,800 psi (not at max flow) for demanding structural and deep‑foundation work.

-

Remote control with start/stop, variable flow, RPM adjustment, and digital readout of flow and pressure.

-

Compact footprint and roughly 2,800–3,000 lb operating weight, making it easy to transport on common trailers.

Top 4 job types and applications

-

Soil nail and rock anchor grouting on slopes, retaining walls, and tunnel portals.

-

Tieback and ground anchor installations for shoring systems and excavations.

-

Micropile and deep‑foundation grouting on bridge, building, and infrastructure projects.

-

Bridge repair and general structural grout injection where high‑volume, high‑pressure cementitious grout is required.

Intric PS‑300 overview

The Intric PS‑300 is a Made in the USA, high‑output grout pump station built to give contractors consistent, high‑pressure grout delivery on deep foundation and heavy civil projects. Its compact modular skid carries a powerful diesel‑driven hydraulic system and piston pump, supplying steady flow and pressure so crews can keep production drilling and grouting moving on busy jobsites instead of waiting on under‑sized equipment. Designed for reliable performance in tough field conditions, the PS‑300 simplifies setup, operation, and maintenance with centralized controls, clear gauges, and rugged hose connections that stand up to daily use. Available for rent or sale through National Piling Products, the PS‑300 can be mobilized quickly as part of a complete, field‑proven grouting package tailored to micropiles, anchors, soil nails, and bridge repair work.

Why rent or buy the Intric PS‑300 from NPP

National Piling Products focuses on deep foundation and grouting solutions, supplying rental drill rigs, Intric grout equipment, materials, load testing services, and field consulting dedicated to micropiles, anchors, and soil nails. Because the PS‑300 lives both in the NPP rental fleet and on the sales line, it arrives set up for real‑world production grouting—hose sizes, pressures, and controls matched to neat and sanded mixes—rather than as a bare factory pump that needs extensive field tweaking. NPP keeps Intric PS‑300 units and critical wear parts in stock, helping contractors boost production and uptime whether they choose a long‑term purchase or a project‑specific rental. Working with an authorized Intric partner also gives you access to knowledgeable support that understands how the PS‑300 integrates into a complete grout plant, not just the pump itself.

Pair the PS‑300 with the right mixer and drill

The Intric PS‑300 really shines as part of a complete grouting system, paired with Intric mixing stations and, on larger jobs, full grout plants that can take advantage of its high pressure and output. National Piling Products can match the PS‑300 with high‑shear mixers and limited‑access drill rigs so drilling, mixing, and pumping capacities stay aligned from submittals through production. By combining the PS‑300 with TEI and Comacchio rigs and additional Intric grout equipment from the NPP fleet, contractors get an integrated drilling and grouting solution where mix designs, volumes, and pressures are coordinated to keep piles, anchors, and nails advancing without starving the pumps. That coordination helps reduce downtime, improve grout quality, and makes it easier to hit production targets on challenging schedules.

Top‑notch mechanic shop and support

NPP’s operation is backed by a mechanic team with years of specialty setup and repair experience on deep foundation equipment, including Intric pumps and mixing stations, Comacchio rigs, and TEI attachments. This shop maintains the rental fleet, supports custom PS‑300 configurations, and assists your crews through commissioning, production, and demobilization so the pump station stays an asset instead of a jobsite bottleneck. Whether you own or rent the PS‑300, you get responsive technical and mechanical support for troubleshooting, parts, and performance tuning in the field. That level of support helps protect your schedule and budget when projects get complicated.

Get in touch

Visit National Piling Products’ YouTube channel for equipment walk‑throughs, grouting tutorials, and field tips focused on micropile, anchor, and soil nail work. For PS‑300 rentals, sales, or application questions—or to discuss pairing the PS‑300 with Intric mixing systems and TEI or Comacchio drill rigs—call 1‑855‑801‑7453 to speak with the National Piling Products team.